General Specifications

Mechanical Data

| Item | Standard Value | Unit |

|---|

| LCD panel |

76.84(W) × 63.84(H) × 4.53 |

mm |

| PCB |

100(W) × 82(H) × 1.6 |

mm |

| Housing outline |

NA |

mm |

General information

| Item | Standard Value | Unit |

|---|

| Operating voltage |

5 |

Vdc |

| Communication Interface |

CAN bus differential ± 3.3 |

Vpp |

| Size |

3.5 |

inch |

| Dot Matrix |

320 × 3(RGB) × 240 |

dots |

| Module dimension |

76.84(W) × 63.84(H) × 4.53(D) |

mm |

| Active area |

70.08(W) × 52.56(H) |

mm |

| Dot pitch |

0.073(W) × 0.219(H) |

mm |

| Backlight Type |

TFT, Normally Black, Transmissive |

| Viewing Angle |

80/80/80/80 (IPS) |

| Aspect Ratio |

4:3 |

| With /Without TP |

With Projected Capacitive Touch Panel (PCAP) |

| Surface |

Glare |

Absolute Maximum Ratings

| Item | Symbol | Min | Typ | Max | Unit |

|---|

| Operating Temperature |

TOP |

-20 |

- |

+70 |

℃ |

| Storage Temperature |

TST |

-30 |

- |

+80 |

℃ |

Electrical Characteristics

Operating conditions:

| Item | Symbol | Condition | Min | Typ | Max | Unit |

|---|

| Supply Voltage For Analog |

VCI |

- |

4.75 |

5 |

5.5 |

V |

| Interface Operation Voltage |

IOVCC |

- |

3.234 |

3.30 |

3.367 |

V |

| Supply LCM current |

ICI(mA) |

- |

XXX |

XXX |

- |

mA |

Interface Pin Function

CON2 definition:

| Pin | Symbol | Function | Remark |

|---|

| 16 |

+5V |

Power supply 5V input |

Input |

| 15 |

GND |

Power supply GND input |

Input |

| 14 |

CAN_High |

CAN bus D+ |

I/O |

| 13 |

CAN_Low |

CAN bus D- |

I/O |

| 12 |

GND |

Power supply GND input |

Input |

| 11 |

GND |

Power supply GND input |

Input |

| 10-1 |

NC |

Connection |

- |

CON3 definition:

| Pin | Symbol | Function | Remark |

|---|

| 16 |

VMCU |

3.3V power for JTAG interface |

Output |

| 15 |

JTAG_SWCLK |

CLK pin for JTAG interface |

Input |

| 14 |

GND |

GND for JTAG interface |

Output |

| 13 |

JTAG_SWDI |

Data pin for JTAG interface |

I/O |

| 12 |

NRST |

Reset pin for JTAG interface |

Input |

| 11 |

JTAG_SWDO |

Data pin for JTAG interface |

I/O |

| 11-1 |

NC |

Connection |

- |

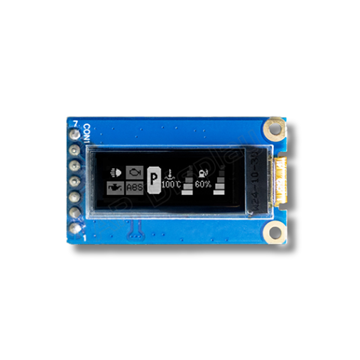

Display Usage

Functional description

Smart Display can be used to display the coordinate, status and data information provided by the connected HOST device. Customers can configure the position coordinates they want to display in normal operation mode (Node ID = 0x7B).

The Display is designed to be easily connected to a controller network, and to operate with minimum setup or knowledge of the SDO configuration on the controllers.

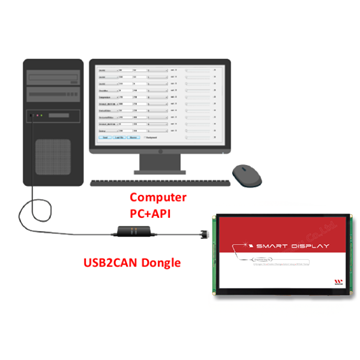

Acquisition of Displayed Data

The Smart Display can acquire the data that it displays either using the CANopen SDO protocol, or using the CANopen PDO protocol.

On Pre-operational mode, customers can set the coordinates of objects through SDO; On operational mode, customers can send data of objects through PDO.

Configuring the Display

Winstar Smart Display CAN series offers an out-of-the-box CANopen development experience that will lower customers' development costs and speed time-to-market expectations.

The Smart Display can use wide-temperature are designed to support control applications in harsh operating conditions, which designed to be connected to a variety of different situation combinations, such as automotive, marine, power generation and oil-and-gas.

The Smart Display comes with standard UI objects to get customers project off the ground quickly. If customers need custom UI objects support, our engineers are here to help. Send over your contents in PNG/JPG format, we will send over a new set of UI objects within 3~5 working days.

The Smart Display is defined as a slave device, which is controlled by master device via CAN bus command to render display content on the display screen and return touch event data with protocol objects.